Product Series

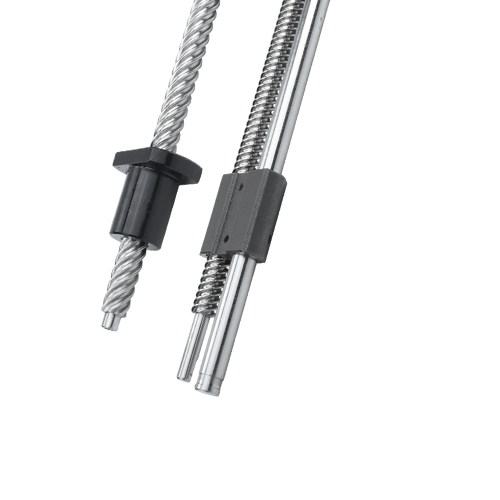

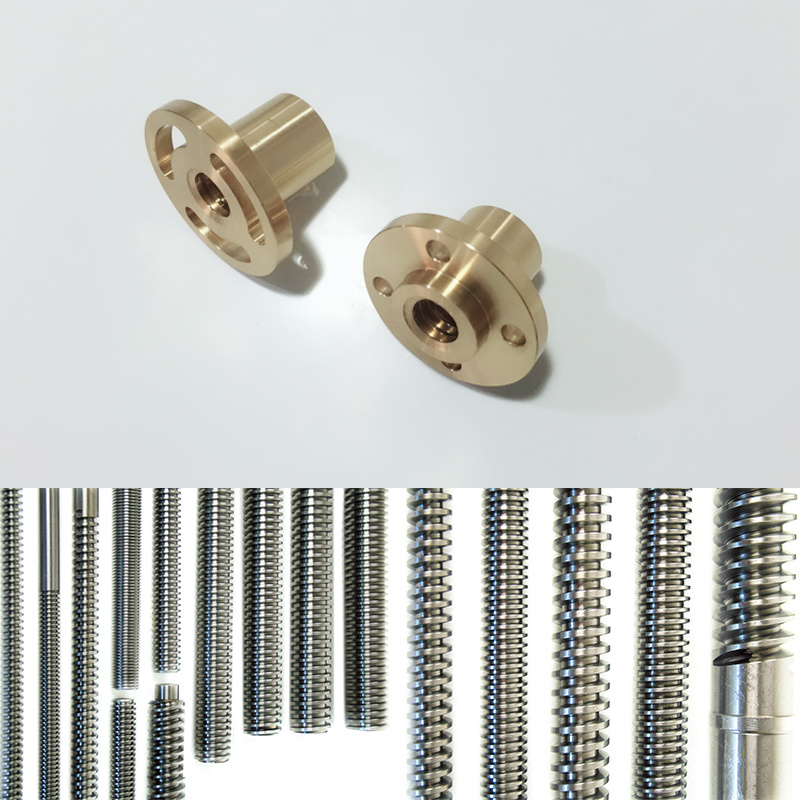

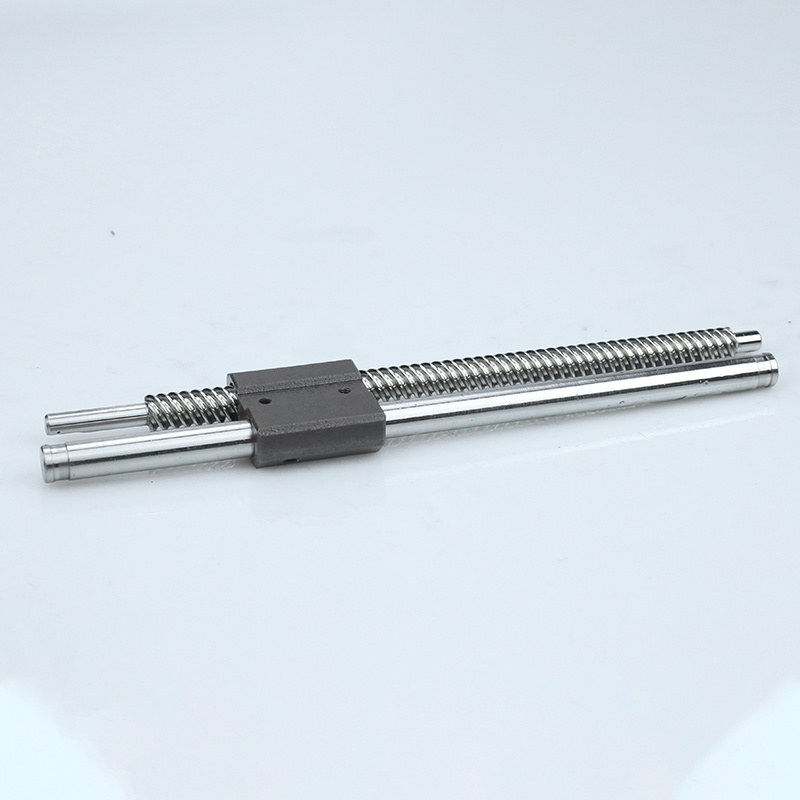

Professional research and development and production of innovative linear motion products and cold rolling thread full range of leading suppliers, the main products are standard trapezoidal screw, CJ (high speed) sliding screw and matching nuts, etc.

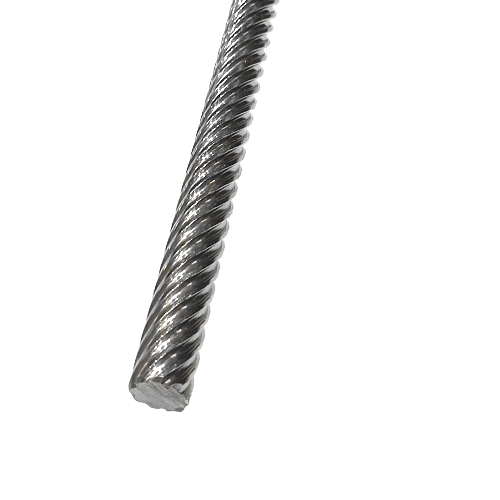

The miniature sliding screw adopts stainless steel screw shaft and sliding resin nut, which achieves excellent corrosion resistance and mute performance without grease.

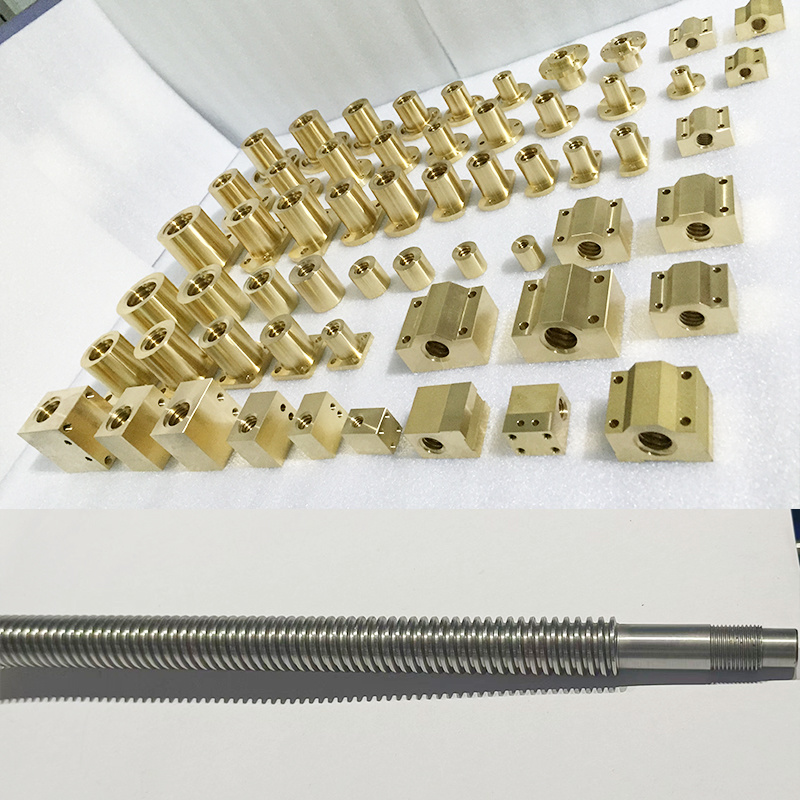

Large lead screw, nut products, widely used in domestic and foreign rail transportation equipment, automotive equipment, and industrial automation transmission field. The main features are high safety and reliability, good comfort and aesthetics, good maintainability, and strong adaptability.

Compared with the ball screw, the standard trapezoidal sliding screw has the advantages of large friction, low transmission efficiency and relatively fast wear. Widely used in a variety of ordinary machine tools and lifts and other industrial equipment

1. Surface non-stick and moisture resistance;

(2) heat resistance;

3. Self-lubricating property;

4. Wear resistance;

5. Corrosion resistance and atmospheric aging resistance;

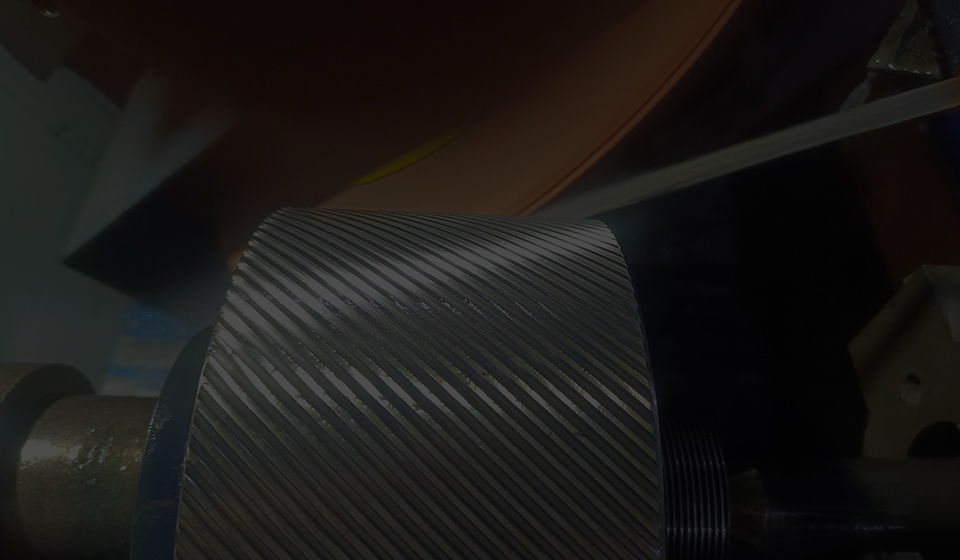

Electroless Nickel Plated Screws

Electroless nickel plating is the use of metal salts and reducing agents, in the material, the surface of the self-catalytic reaction to obtain a coating method.

Molybdenum disulfide metal surface coating is a kind of high temperature resistant anti-corrosion antifriction coating, coating in high temperature environment chemical performance is stable, non-toxic harmless, non-corrosive, insoluble in other solutions

Hot Products

Main products: standard trapezoidal screw, micro screw, large lead screw, semiconductor screw and matching nut, etc

Evergreen Precision Wire Rod Company Established

Floor Area

On-the-job staff

Exporting Countries and Regions

Leading supplier specializing in the development and production of innovative linear motion products and a full range of cold rolling threads

01

Main Products

The main products are: standard trapezoidal screw, CJ (high-speed) sliding screw and matching nut, high-speed multi-head drive screw, etc.

02

Scope of application

Widely used in medical equipment, instrumentation, industrial equipment, mechanical automation, machine tool equipment, door and window drives, urban rail transit carriage doors, smart furniture, new energy vehicles, solar power generation, semiconductor equipment, electric vehicle transmission components and other industries

SINCE 2006

Nanjing Evergreen Precision Screw Manufacturing Co., Ltd.

Founded in 2006, Evergreen is a leading supplier of innovative linear motion products and a full range of cold rolling threads. The factory is located in Zhangzhou, Fujian, China, covering an area of 5000 square meters, 40 employees, 6 R & D personnel, 6 technical personnel.

The main products are standard trapezoidal screw, CJ (high-speed) sliding screw and matching nuts. High-speed multi-head drive screws are widely used in medical equipment, instrumentation, industrial equipment, mechanical automation, machine tool equipment, door and window drives, urban rail transit carriage doors, smart furniture, new energy vehicles, solar power generation, semiconductor equipment, electric vehicle transmission components And other industries, the company has long provided customers with unique products and a full range of product design, mold manufacturing, manufacturing, verification testing, and after-sales service.

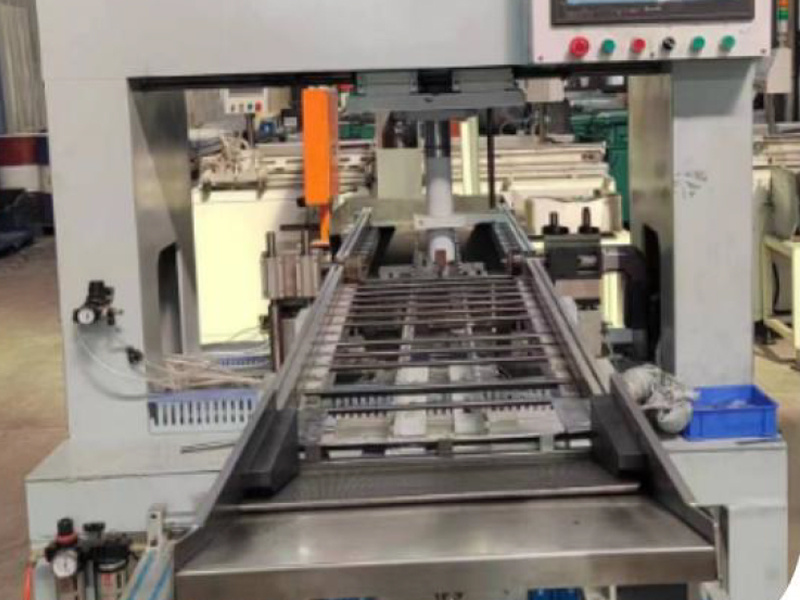

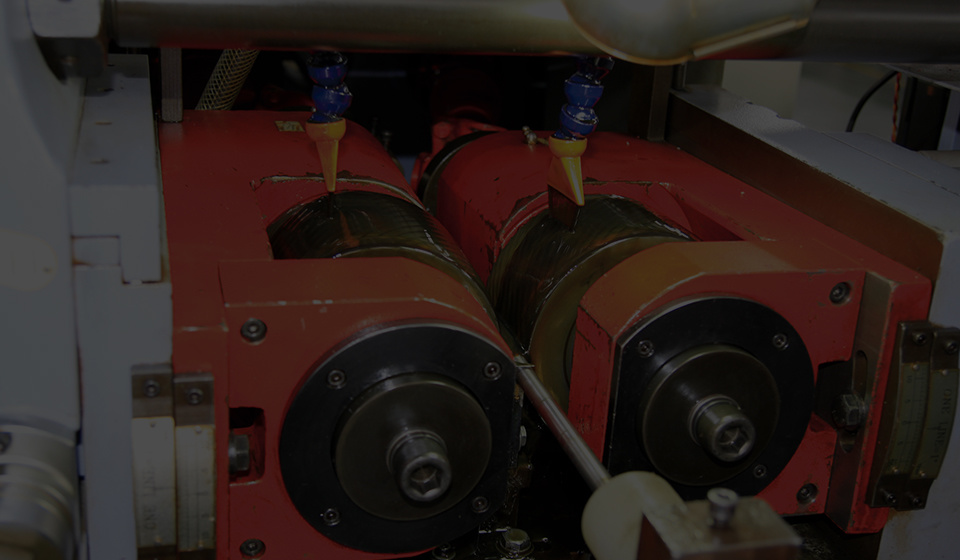

Production Equipment

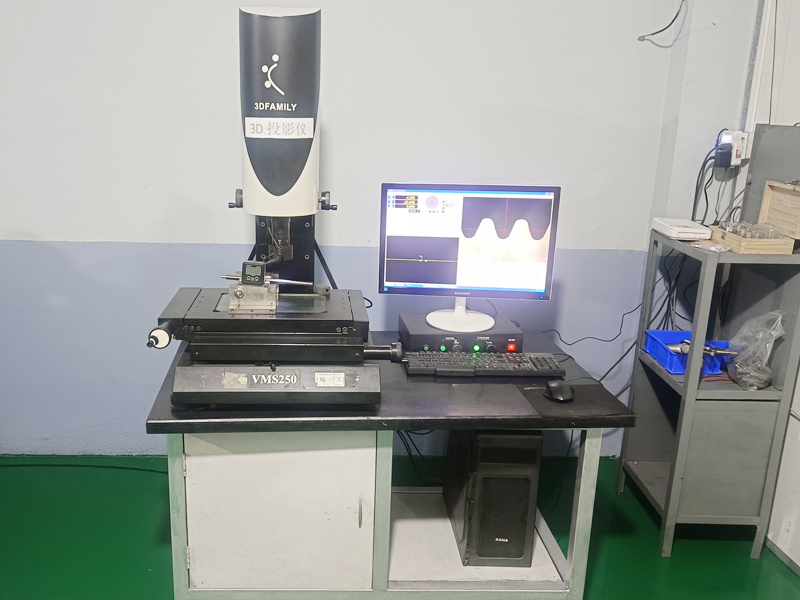

Testing equipment

Quality Products

The company has passed the intellectual property management system certification, obtained the new version of ISO900:2015 system certificate, the products have passed the customer test verification, but also won the national national high-tech enterprise title

Production Strength

At present, the company has professional sliding screw testing and testing, including special screw numerical control rolling production line, automatic straightening production line, automatic loading and unloading turning and milling production line, automatic loading and unloading polishing production line and ultrasonic automatic cleaning line, rolling mold manufacturing numerical control workshop, with the automation degree of production workshop reaching more than 50%

News Centre

Dedicated, passionate and competitive professional team, people-oriented focus on design and sliding screw manufacturing, providing solutions for innovative products of precise linear motion

Need us to help youFind the right solution?

Please contact our professionals.

For more product updates, please leave your email and we will contact you within 24 hours.